What is "Bleed"?

How do I prepare the files to print bleed?

Visual Explanation & Examples Easy to Understand for Color Copy Bleed

Hot Topic! The short story about bleed

This first piece "bleeds":

.

The image gets to the edge of the paper so your file requires an appropriate preparation

Read the article below

This next piece does not "bleed":

The image does not get to the edge of the paper.

Bleed in a color copy: It is probably the most confusing characteristic in file preparation. Whether dealing with a PDF file or photo printing, if you work mostly with home-desktop-style-publication software, you will probably find many things to think about the next time you prepare a document that will print as a color copy bleed job

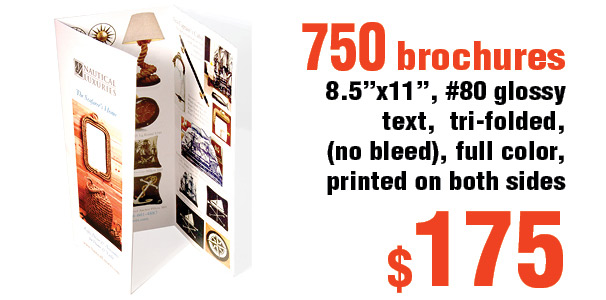

Bleed Color Copy projects such as: Color Copies, Brochures, Sell Sheets, Books, Posters and more. Best practices for use and design of publications and documents that will print with bleed.

We hope that you find the next three topics useful.

- What is bleed exactly?

If you are unsure, click here for an answer

- Read 3 reasons why bleed should be used

Why would you want to have "bleed" into your document. Is there any advantage or disadvantage to getting or not getting bleed?

To read those reasons, click here

- How do I prepare my files in the right way so that the printer will be able to print PDF files and photo prints as intended? Does the printing cost change?

Click here to learn about file preparation and cost impact

What is bleed exactly?

Bleed: Look at a Modern Picture that bleeds!: When you get your pictures developed at a Kodak Store (or Walgreens or CVS for the matter), your pictures will usually take all of the photo's paper. You'll get something that looks like this printed picture with bleed shown here:

On this picture the image gets right to the edge of the paper.

The printed area covers 100% of the printable area!

No Bleed: This next other picture does not bleed

An Old Family Picture that Does Not Bleed. This is how pictures used to look like a few years ago. Regardless of the cultural changes that occurred, these two images (the one on top and the one ahead) illustrate what bleed is about

On this picture the image does not get right to the edge of the paper. There is a thin white border

The printed area covers less than 100% of the printable area!

How to prepare a file so that it prints with bleed?

Let's look at how modern documents are created. We'll look now at commercial printing. Color printing allows to reproduce the same scenarios that were described for family pictures.

The image bellow shows a full bleed piece seen from the perspective of a printing company. The image reflects what the company, reproducing and printing the piece, needs to get at their digital color printing equipment or printing press. If the printed piece at the printing company does not look pretty much like the image bellow, it will be difficult to obtain a high quality piece.

What should I do then??

There is no "commercial or industrial" way of printing a piece of paper right to its edge without taking the risk of having a thin undesired white border, or without making the back of the printed side dirty (offsetting).

Here's what needs to be done:

The way in which a piece with bleed is produced requires the following situations to take place:

- The printing company needs to print in excess of what the final piece's size is required. The excess is usually 1/8" in US and about 3 to 5 mm. where the Metric System is used.

- Once printed with the excess explained, that excess must be removed to bring the piece to the actual required size, a process known as trimming.

This image on our left, presents the same information in the printing lingo

So a file that is created to be printed with bleed needs to be bigger than the final size of the final piece.

FILE PREPARATION and PRINTING COST

We will take as an example, a printed piece that once trimmed, will have an overall size of 8.5" wide x 11" tall. In your layout software set for an image size of 8.75"x11.25". The next paragraph explaines how we came up with that number.

Width: You should add 1/8" to each side of your piece,

so the width should be set to: 8.5"+2x1/8"

which is the same as 8.5"+2x0.125" which equals 8.75"

Height: the same concept applies, so if the height of the document is to be 11", then the image in the file should be 11.25".

PRINTING COST: What does this bleed requirement mean in terms of the cost of printing with bleed:

• The paper size needed is bigger than 8.5"x11". Printing on a larger piece of paper becomes more expensive

• The paper needs to be trimmed. Trimming is a process that requires additional equipment and labor, therefore increasing the production costs.

A BIG ALERT NOTE: Keep in mind that the portion of the image that is printed outside of what is going to be the final size of the piece will be trimmed and removed. So the part of the image that goes into the bleed area should be the extra image that will go once trimmed.

What's the biggest error some designers do? Some people just expand the image that they want on their final piece. This is a mistake because expanding the image will result in trimming. Trimming removes part of the image so it results in a final piece that is different to what was expected.

Rule #1 for Bleed: Create bleed with "additional image", not by expanding your image

3 reasons to have your document bleed

- Bleed allows for a more focused view

- Bleed allows for more attractive visual impact.

Please observe the effect of bleed/no-bleed on a simulated book cover.

Left Image: No bleed on the cover.— Right Image: Bleed! Our choice!

- Documents that bleed are usually viewed as being "more professional". That means more efficient marketing actions.

Amateur documents, on the other hand, designed through

home-desktop-publishing software usually have thick white borders

This first image corresponds to a non-bleed scenario where your design opportunities become very limited

The second scenario that uses bleed permits larger pictures,

cropping and enhancing details through zooming

I believe that the invitation on the left offers less distraction than the piece on the right hand side. The impact is that the viewer of the piece on the left will be exposed to the message in an easier way. The eye focuses on the title right away other than panning the whole piece trying to decide where to start.

The inviation on the right requires more time to focus on its message.

Borderless pictures are called pictures that "bleed". Because there's no white frame, in order to get it done properly, you must get the photograph printed on a slightly large paper and trimmed. In that way, you make sure that no white edge will be present.

The same concept is utilized in printing. Either in the case that you're printing brochures, of printing color copies, or door hangers, or business cards, every time you want your images to bleed, the printing house will need to use oversized paper that will later be trimmed to size:

Oversized papers are more expensive than the standard papers just described because a) there's more paper and b) once printed, there's a need to further process the printed piece.

Let me explain: If you're color printing on an 8 1/2" x 11" page without bleed, you take the paper in the final size, print it with the proper equipment, and you're done.

But if what you want is an 8 1/2" x 11" piece that bleeds, then you need at least a sheet of paper that's 9" x 12" (I'm sure that you already realize that the additional paper around what you actually expect to get is a "long piece" of about 1/2"inch with by 42" long (perimeter). That extra paper in turn needs to be cut down to size. To cut paper with precision you require an expensive cutter, with sharp blades and skilled operators to get things done.

As you can see, printing a color copy bleed project requires some knowledge but is not that easy to do. Let us know if we can help.

go back to top

Our Color Copy Process | Order Color Copies

by Gustavo Baner 2009-2011©